Mold cleaning is a key process in mold maintenance. At present, the speed of mold manufacturing and development is much faster than the speed of mold cleaning, and the mold needs to be prepared for the next production immediately after rapid cleaning, so the time left for mold cleaning is quite limited. Whoever can produce the same quality product at a lower cost can win the market, and whoever can clean the mold at a lower cost can become the main process of mold cleaning.

The traditional mold cleaning methods include mechanical grinding, chemical cleaning, dry ice cleaning, etc. Among them, dry ice cleaning is the most widely used. But after a long time of use, the drawbacks of dry ice cleaning will become apparent. The biggest drawback of dry ice cleaning is that it is easy to evaporate, the loss is large, and the storage is also very difficult.

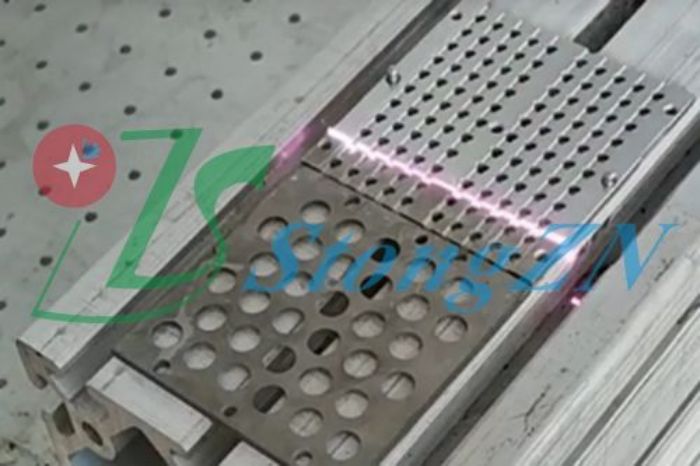

Laser cleaning is a new type of green and environmentally friendly cleaning method that can clean molds without hurting them. When laser cleaning technology emerged, its advantages were in sharp contrast to traditional mold cleaning methods. There were no other consumables in the laser cleaning process, and the cost was much lower than traditional cleaning. It had the advantages of high cleaning efficiency, no need to cool the mold, no need to disassemble the mold, low labor intensity, high cleaning quality, green cleaning, no damage to the mold, safety and reliability, wide adaptability, easy to use computer control, and high degree of automation.

The advantages of laser cleaning molds are unmatched by other cleaning methods, and it also has a real cost reduction and efficiency advantage for enterprises. With the breakthrough of domestic laser technology, the power and performance of laser cleaning equipment will become more and more abundant, and it will become the mainstream method of mold cleaning. Laser cleaning machines have broad development prospects in this field.